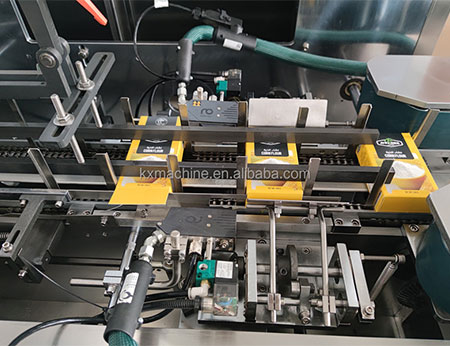

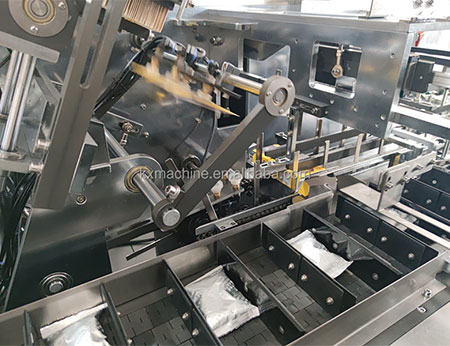

The KXZ - 130B Automatic Bulk Food Cartoning Machine is made for food packaging. It can handle grains, nuts easily, running at 80 cartons per minute with under 1% error rate. Many top food firms recommend it as it cuts costs and boosts efficiency.

The KXZ - 130B Automatic Bulk Food Cartoning Machine is designed for food packaging. It can handle various bulk foods like grains, nuts. With high - speed operation and stable performance, it ensures efficient packaging.

|

Encasing Speed |

30-60boxes/min |

|

|

Box |

Quality requirement |

250-450g/m2 (according to its dimension to confirm) |

|

Dimension range (L×W×H) |

(70-250)mm×(50-120)mm×(35-105)mm can customize according to your requirement |

|

|

Compressed air |

Working pressure |

≧0.6mpa |

|

Air consumption |

20m3/h |

|

|

Power supply |

380V 50Hz |

|

|

Motor power |

1.5KW |

|

|

Machine dimension (L×w×H) |

4600*1350*1900mm |

|

|

Machine weight |

1800KGS |

|

GET A QUOTE